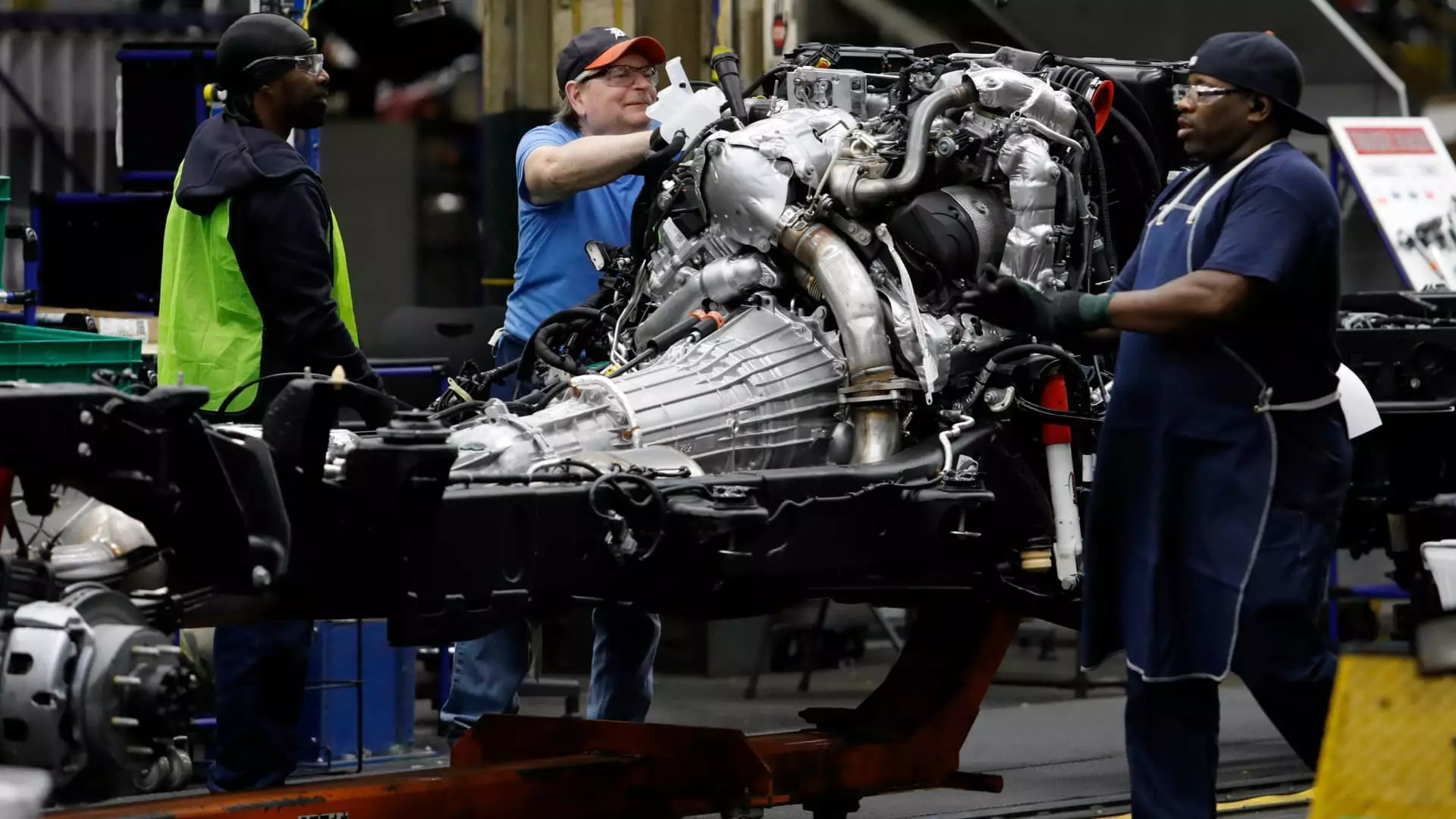

In a significant blow to General Motors (GM), the automaker has been forced to pause operations at two key factories within the United States due to supplier disruptions stemming from Hurricane Helene. This temporary halt affects the manufacturing of GM’s lucrative line of large pickups and SUVs, which are major contributors to the company’s revenue. The Flint, Michigan, facility, known for assembling heavy-duty trucks, along with the Arlington Assembly plant in Texas, which specializes in full-size SUVs like the Chevrolet Tahoe and Cadillac Escalade, are now experiencing canceled shifts as a result of this severe weather event.

Hurricane Helene has wreaked havoc since making landfall in Florida, spreading devastation across the southeastern U.S. and western North Carolina. Reports highlight the tragic loss of life, with over 215 fatalities and numerous individuals still unaccounted for. GM’s decision to suspend production is a clear acknowledgment of the ripple effects severe weather can have on supply chains, particularly in industries as reliant on timely component deliveries as automotive manufacturing.

Communication and Future Outlook

Despite the disruptions, GM has prepared its workforce for potential contingencies. A memo disseminated to employees at the Arlington plant indicated that operations might resume as early as Monday. However, GM has refrained from providing specific timelines for restarting production at either facility, reflecting the complexity of coordinating with affected suppliers and addressing any lingering operational hurdles.

In the midst of this turmoil, GM has communicated its commitment to collaborating closely with suppliers to ensure a swift return to normalcy. The company’s statement emphasized a focus on safety for both employees and local communities as they navigate the intricacies of resource allocation and production scheduling. The transparency regarding ongoing challenges is crucial in maintaining operational integrity and employee morale during this tumultuous period.

Proactive Measures and Supply Chain Resilience

Jeffrey Morrison, GM’s vice president of global purchasing and supply chain, underscored the broader context of these disruptions, pointing out that they follow the complexities faced during the pandemic. As businesses adapted to COVID-19’s challenges, they were compelled to reassess their supply chain dynamics more critically. Morrison noted that the pandemic has allowed GM to conduct a more thorough mapping of its supply chain, resulting in greater visibility into sub-tier suppliers and their respective vulnerabilities.

The automaker’s efforts to strengthen its resilience against unforeseen events reflect a strategic pivot towards enhanced supply chain management. By deepening its understanding of the various components that feed into production, GM equips itself to preemptively address disruptions, an essential capability in a rapidly changing global landscape. Furthermore, Morrison’s acknowledgment of the importance of supporting suppliers during production challenges echoes the collective responsibility manufacturers share in fostering industry stability.

The challenges posed by Hurricane Helene serve as a reminder of the fragility inherent in supply chain systems. For GM, the ongoing situation illustrates both the immediate impact of natural disasters on production and the imperative of evolving supply chain resilience strategies. As the automotive giant works through these turbulent waters, its response will be closely monitored, not just by industry insiders, but by a public eager to see how well the company can navigate adversity while ensuring safety and stability for its employees and suppliers alike.

Leave a Reply